Bench Test Alternator

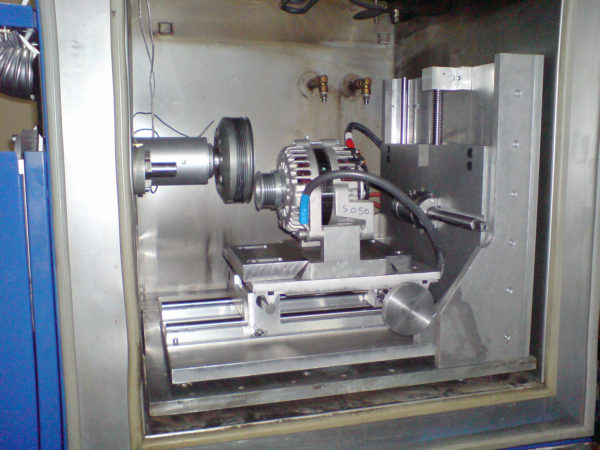

The onyx test bench is a complimentary tool to our old bosch test bench.

Bench test alternator. This video will cover the following how to test an alternator using multi meter how to replace an alternator how to diagnose alternator charging issues alternator ripple test how to test a. Test alternator by connecting voltmeter on dc 20 red on positive battery terminal and black on negative battery terminal. 18 wide x 2 1 high x 24 deep. All the regulator does is connect the brushes to the supply until some voltage between 13 and 14 volts is reached.

Dont forget if the test does work you will get a substantial torque reaction at the drill apart from needing a pretty beefy one any way. Start vehicle and voltage on voltmeter should increase to around 13 volts and stabilize there. Before starting remove the regulator from the vehicle. Testing of 6 12 24 32 volts optional.

We can also print a ticket of the test result and give it to our customers they do appreciate it. How to bench test an alternator regulator. The fast and easiest way to test an alternator with a drill a socket and multimeter this way by spinning will produce electricity and therefore test for its functionality please like a share. If it decreases and starts to drop until vehicle eventually dies you have a defective alternator.

How to test an alternator testing the voltage regulator diode rectifier and stator duration. Junky diy guy 1568269 views. Tests all american alternators starters. 10 test leads for late models alternators.

2 step pulley 3 and serpentine. The output from the regulator is monitored while. Please read the entire procedure before starting. 230 volt 60 hz motor.

5 hp single phase motor. Tests all foreign made with additional harness leads. Its simplicity and capacity to test the alternators with the latest regulators allows us to repair all alternators on the market. That is all this procedure checks.

Check output pins from alternator too for accurate voltage readings and connections. I have a 60 a alternator connected to a briggs mower engine and had to remove thr regulator as the alternator would take all the engines power and bog it downto a stall.